Kawasaki Robotics will showcase new additions to its extensive robotics portfolio, including the CL Series of intelligent collaborative robots (cobots), at the International Manufacturing Technology Show (IMTS) in Chicago from September 9-14. The CL Series cobots, available in various payload capacities, along with new industrial robotic solutions for welding, machine tending, and material removal, provide manufacturers with enhanced flexibility and capabilities to meet their automation needs.

“Kawasaki Robotics is dedicated to delivering advanced automation technology that allows manufacturers to maintain production schedules without compromising quality or safety,” said Seiji Amazawa, President of Kawasaki Robotics. “By partnering with innovative companies such as AMT, Hurco, Wauseon Machine, and NEURA Robotics, we integrate our technology with theirs to leverage the best in human ingenuity.”

CL Series: A “New Era” of Collaborative Automation

Developed in collaboration with NEURA Robotics, the CL Series cobots redefine the capabilities of collaborative robots by offering industrial-grade performance and speed while maintaining the safety and flexibility benefits of human-robot collaboration. Compact and durable, the CL Series cobots utilize the same robust casing as Kawasaki’s industrial robot arms and can operate without protective covers in crowded and harsh environments, making them ideal for tasks like machine tending and welding. Operating in Zero Gravity (Zero G) mode, these cobots require minimal guidance to achieve high efficiency.

“With the CL Series cobots, we’re entering a new era of collaborative automation,” said Amazawa. “By offering industrial-scale performance and speed as standard features, we enhance productivity, improve quality, and increase worker safety, all while helping manufacturers address labor shortages and achieve a strong return on investment.”

The CL Series supports a range of payloads, from 3 kg/590 mm to 10 kg/1000 mm, with future models offering up to 15 kg. Built with high-quality components, such as integrated 24-bit encoders, the cobots achieve industry-leading speeds of 200°/s and a repeatability of ±0.02 mm. The user-friendly interface simplifies automation processes, while its free mounting orientations, small footprint, and IP66 classification provide unmatched flexibility. Advanced safety features, including limits and collision detection, ensure the CL Series cobots can work safely alongside human operators.

At IMTS 2024, Kawasaki Robotics will demonstrate the full CL Series cobots in a cooperative motion display. A CL110 cobot will be shown tending a Wauseon Machine 1004EL Electric End Forming Machine, while an interactive display will allow users to experience the CL Series’ Zero G mode by hand-guiding a CL108 cobot to record programs with ease. The saved parameters improve setup consistency and reduce errors.

Other Robotic Solutions at IMTS

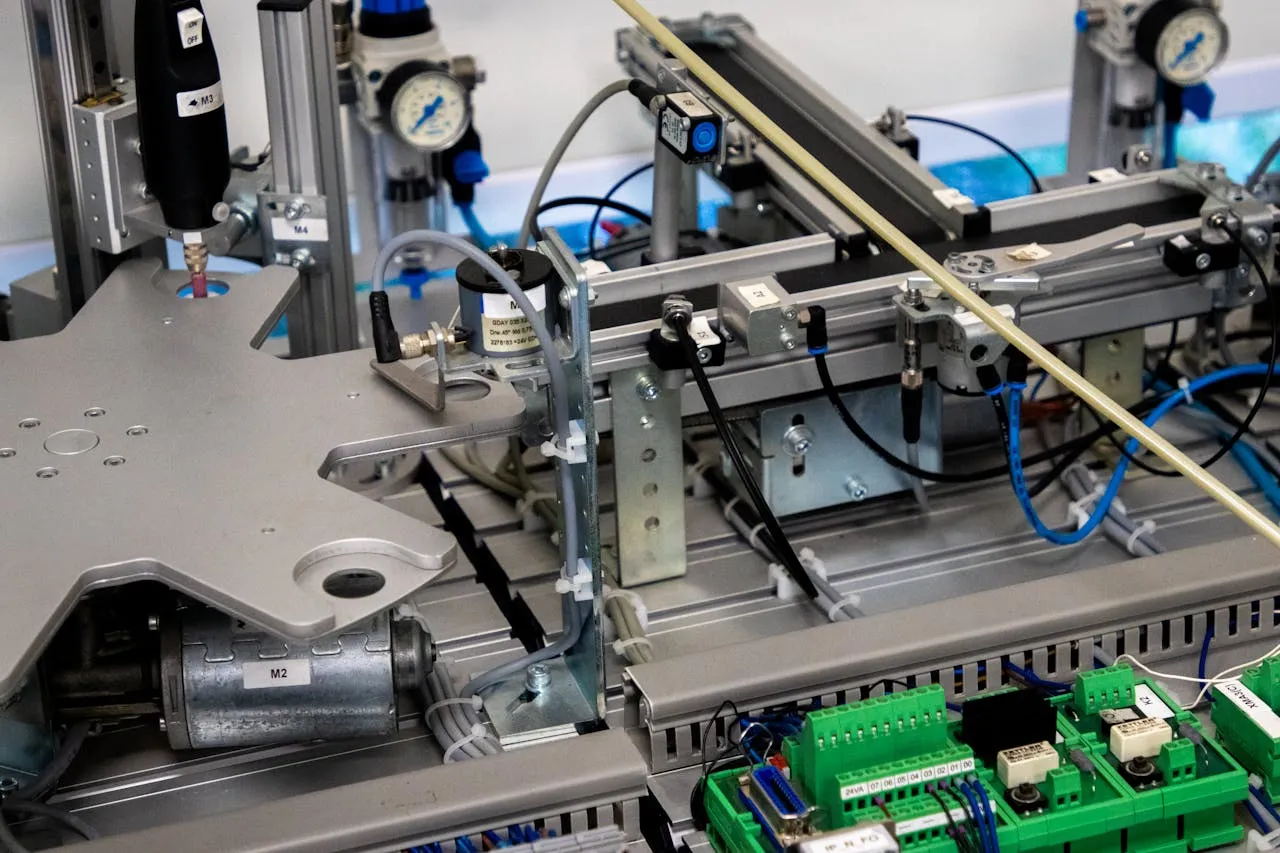

- Robotic Machine Tending Shelf System: Developed with Hurco, this turnkey solution offers an easy-to-set-up, modular shelf system for part feeding. The demo will feature a Kawasaki RS013N robot working alongside a Hurco VM15Di CNC machine, operated via Hurco’s WinMax CNC Controls, enabling high-mix, low-volume manufacturing without requiring complex robot programming.

- Welding Robots: Kawasaki will feature its BA013N and BA013L welding robots, known for their state-of-the-art technology, including real-time path modification, adaptive arc welding, and RTPM capabilities, to improve manufacturing quality and meet production goals.

- Robofin: In partnership with AMT and NEFF Automation, Robofin provides a versatile material removal solution capable of handling diverse materials and surfaces. It increases abrasive life by up to 3X while delivering consistent, high-quality finishes.

- K-Positioners: These positioners allow robots to manipulate workpieces for optimal welding torch angles, speeding up production while reducing rework.

- K-Tracks: This solution allows for flexible reconfiguration of production lines, reducing the need for multiple robots and enabling manufacturers to quickly adapt to changing demands.

Learn more about the CL Series cobots and Kawasaki Robotics’ full portfolio at IMTS, booth 236520. The ASTORINO educational robot, introduced in mid-August, will also be showcased at booth 121415 during the IMTS Smartforce Student Summit