Veryon Enhances Diagnostics Suite with AI-Driven Parts Predictability and Reliability Solution

Introduction

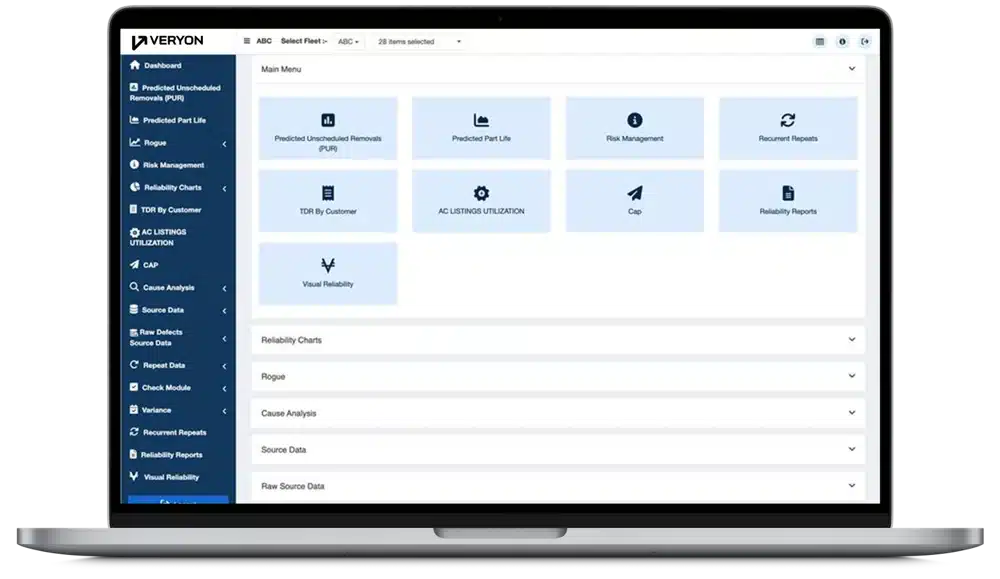

Veryon, a leading provider of aviation information services and software solutions, has announced a major expansion of its Diagnostics suite with the introduction of Veryon Reliability. This AI-powered solution integrates advanced parts predictability, fleet reliability, and reporting capabilities to help aircraft operators and OEMs optimize maintenance planning, reduce unscheduled downtime, and enhance overall fleet availability.

Transforming Aircraft Maintenance with AI-Driven Predictability

As the aviation industry evolves, minimizing operational disruptions remains a key challenge. Unscheduled maintenance events, particularly those driven by parts failure and availability issues, significantly impact fleet efficiency. Veryon Reliability addresses these challenges by integrating machine-learning algorithms and pattern recognition technology to detect failure trends, predict short-life components, and identify rogue parts before they fail.

“With Veryon Reliability, we are equipping operators with AI-powered failure predictions, real-time parts forecasting, and automated reliability insights,” said Kris Volrath, Senior Vice President of Product at Veryon. “This expansion represents a significant advancement in our predictive maintenance capabilities, allowing operators to transition from reactive repairs to proactive decision-making that enhances aircraft availability, reduces maintenance costs, and improves operational efficiency.”

Seamless Integration for Enhanced Fleet Reliability

The introduction of Veryon Reliability marks the next step in the evolution of predictive aviation maintenance. Previously known as RCMBT Reliability Decision Support Systems (RDSS), the solution is now fully integrated with the Veryon Diagnostics platform, creating a comprehensive, AI-driven reliability suite. By combining data analytics, predictive modeling, and real-time monitoring, Veryon Reliability offers a holistic approach to fleet management, helping operators identify and address potential failures before they occur.

Key capabilities include:

- Predictive Parts Model – Forecasts parts failures, lifecycle trends, and rogue part risks to optimize inventory management and prevent recurring defects.

- Automated FAA CASS Reporting – Reduces the administrative burden of regulatory compliance by automating critical documentation processes.

- Data Cleansing and Integration – Enhances the accuracy and reliability of data for both OEMs and operators, ensuring more effective maintenance decision-making.

- Virtual Reliability Service – Provides professional services, including data analysis, predictive insights, and tailored advisory solutions, allowing operators to focus on core business functions while leveraging Veryon’s aviation expertise.

Bringing AI-Driven Maintenance to the Next Level

The integration of AI and automation into Veryon Reliability marks a major milestone in aviation maintenance. Bethany Little, CEO of Veryon, highlighted the company’s commitment to pioneering intelligent, data-driven aviation solutions:

“Veryon Reliability is another milestone in our mission to transform aviation maintenance. By harnessing AI and automation, we empower operators and OEMs to make proactive, data-backed decisions—resulting in safer, more efficient, and cost-effective operations.”

This AI-powered reliability suite is a game-changer for aviation maintenance teams, enabling them to move beyond reactive troubleshooting into predictive maintenance strategies that maximize fleet performance.

Industry Recognition and Awards

The innovation behind Veryon Reliability has earned industry-wide recognition. The solution was recently named a winner in the 2025 Artificial Intelligence Excellence Awards, presented by the Business Intelligence Group. This prestigious award underscores Veryon’s leadership in AI-driven aviation solutions and its dedication to advancing fleet performance and operational efficiency.

The Artificial Intelligence Excellence Awards celebrate the most innovative companies, technologies, and professionals shaping the future of AI. Winners are selected based on their creativity, impact, and measurable success in AI-driven solutions. Veryon Reliability’s recognition highlights its cutting-edge approach to predictive maintenance and reliability in aviation.

Seamless Implementation and Adoption

Getting started with Veryon Reliability is a streamlined and proven process. Operators can leverage the same implementation framework as Veryon Diagnostics, ensuring seamless data integration and onboarding. With a single data integration, users benefit from:

- Enhanced security protocols ensuring data integrity.

- Faster implementation timelines that minimize operational disruptions.

- Actionable insights that drive immediate reliability improvements.

When paired with Veryon Guided Troubleshooting, operators can rapidly identify and resolve maintenance issues, creating a fully closed-loop solution for fleet reliability and troubleshooting.

Why Veryon Reliability Matters for the Future of Aviation

With thousands of aircraft operators relying on Veryon’s aviation technology platform, the launch of Veryon Reliability represents a significant leap forward in aviation maintenance intelligence.

Key benefits include:

- 23% reduction in aircraft downtime costs through proactive maintenance planning.

- Enhanced fleet reliability and uptime, improving operational efficiency.

- Reduced regulatory burden with automated compliance reporting.

- Improved inventory and parts management through AI-driven forecasting.

As aviation technology continues to evolve, Veryon remains at the forefront of innovation, ensuring that aircraft operators, MROs, airlines, and OEMs can maximize efficiency, safety, and performance.

For more information about Veryon Reliability, visit www.veryon.com.